unmistakable trend

The unmistakable trend towards inline/online process monitoring provides many benefits for the food, pharma and cosmetics industry. This article focuses on the savings in energy consumption in the food industry by monitoring and optimizing the freezing processes.

Evaluating freezing processes is typically achieved by at-line or offline temperature measurements. A quality control manager collects samples from the production line and places a temperature probe in or between products. It takes 10 minutes or more before a reliable temperature readout is obtained. Based on the obtained readings, the freezer settings are adjusted. This quality control approach is time consuming, prone to manual errors, labor intensive, energy inefficient and can result in a significant product loss.

In case of French fries, it is estimated that almost 60% of the total cost of French fries production is related to energy consumption. Nevertheless, freezing units are currently still regulated manually. This can result in insufficient and unregular freezing, affecting the food safety and quality. To be on the safe side, freezing installations are set to lower temperatures than required. This leads to excessive freezing of the products and an increased energy cost.

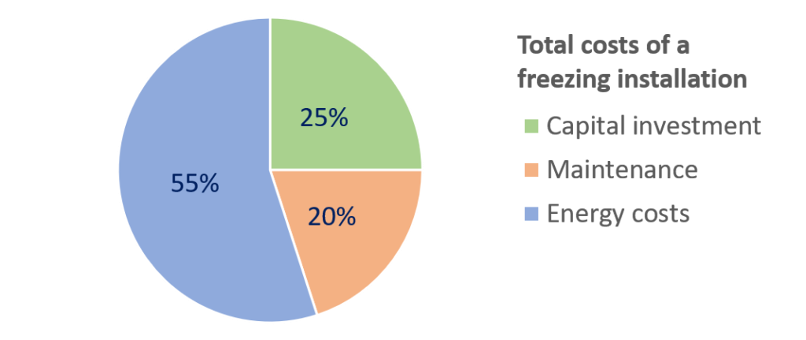

When considering an investment in an industrial freezer with a 20-30-year lifespan, only 25% of the total costs represent the capital investment. The maintenance costs are estimated to be around 20%. However, more than 55% of the total costs are energy costs. Reducing energy costs becomes essential to stay competitive and to meet the quality standards of the customers. At the same time the lifecycle of your freezing-line is extended.

Figure 1: Total costs of a freezing installation.

Aquantis inline freezing sensors – CALLIFREEZE® and MICROFREEZE® – reduce these energy costs with 10-15% while maintaining the highest product quality. These sensors measure the “Level-of-Frozenness” or LOF in real time. The LOF indicates how much of the water inside the product is crystallized into ice. This provides direct and real-time information about the freezing process and product quality.

With the information from these sensors, the freezing parameters (e.g. freezing time, air temperature, etc.) can be adjusted and optimized in real time. For example, by installing the MICROFREEZE® in the freezing process of French fries, the temperature in a standard freezer could be increased with 3°C for the same production capacity and quality. This translates in a saving of +80.000 €/year on a 20-ton line or a return of investment within half a year.

Conclusion

The high energy consumption of freezing demands the need of an improved process control. While conventional methods depend on manual interventions, Aquantis inline sensors provide real-time control over the freezing process. Automation and optimization of the freezing process results in a significant reduction in energy consumption and consequently, the energy costs.