Level-of-Frozenness (LOF)

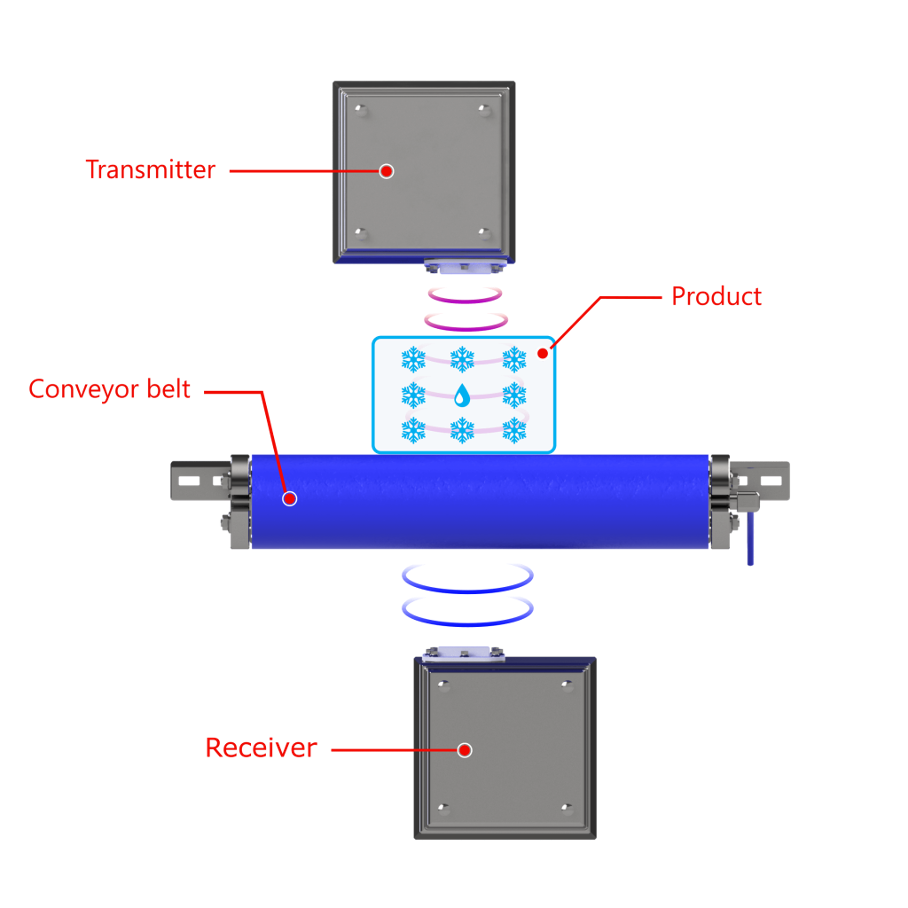

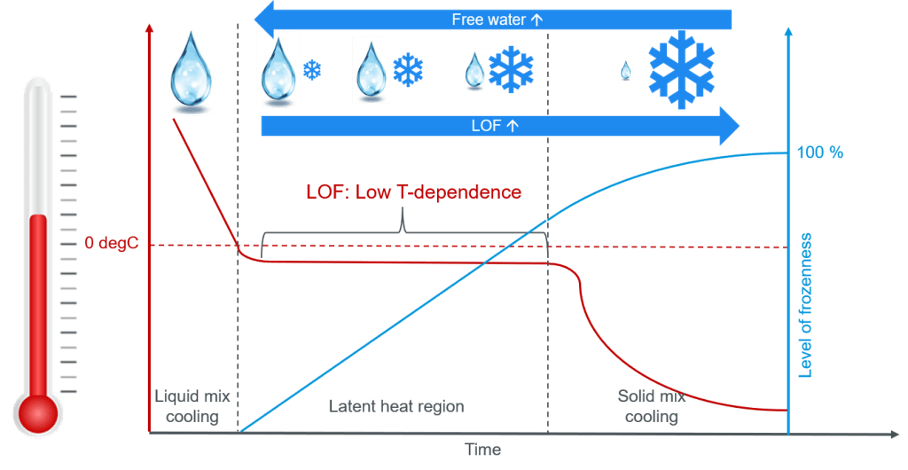

Temperature is an unreliable indicator to monitor freezing & defrosting processes. Once the temperature drops below the freezing point, the water starts to crystallize. During this crystallization process, the ice fraction grows over time, while the temperature remains rather constant (latent heat region). Therefore, Aquantis introduced the use of LOF instead of temperature in order to determine to which extent a product is frozen. Both the CALLIFREEZE® and MICROFREEZE® sensors clearly distinguishes the liquid from crystallized water fractions in food products. This makes it more reliable to determine if your product is properly frozen.

Applications:

Benefits of measuring LOF

Real-time information

Temperature measurements are slow. Typical quality control consists of placing a temperature probe in the product (destructive) or between products. After equilibrium is obtained, the temperature can be read out. This approach is time consuming. The LOF can be continuously measured making it a reliable and accurate indicator of the freezing quality.

Efficient and reliable quality control

Conducting temperature measurements is labor intensive and prone to manual errors. The conventional temperature measurement requires personnel to place the temperature probe correctly in or between the products at regular time intervals. These manual measurements are prone to errors or inaccuracies. Real-time monitoring of the LOF provides consistent measurements and consequently consistent freezing quality of the products. This allows to allocate personnel more efficiently and reduce personnel costs.

Surface vs. Core information

Typical temperature measurements make use of temperature probes or near-infrared sensors to monitor the surface temperature. These measurements are not representative for fast freezing or defrosting processes, layered products or large products (e.g. blocks of products). The surface temperature can differ significantly from the core temperature fouling the measuring equipment. Our freezing sensors measure through the product providing information on the crystallization throughout the entire product. Any unfrozen parts at the core of the product will be detected.