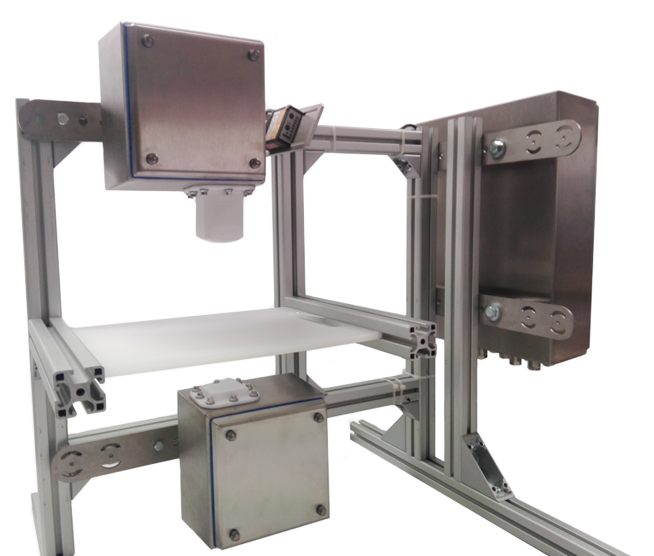

CALLIFREEZE®

The CALLIFREEZE® is specifically designed to measure the LOF of individual products such as meat products, fish, vegetables, etc. This sensor has shown its importance in the market by winning the innovation price of CFIA EXPO 2019 in Rennes, France!

Applications:

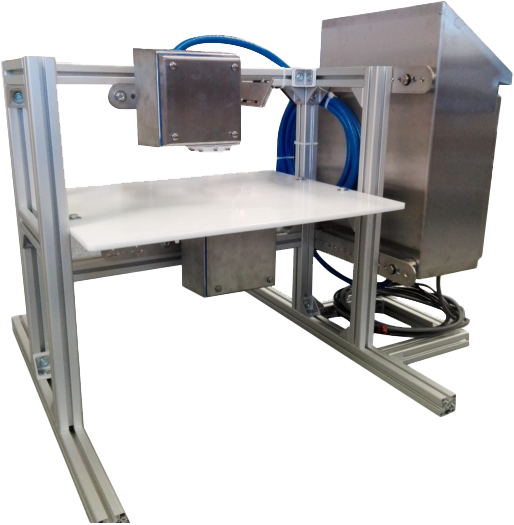

MICROFREEZE®

The MICROFREEZE® is used to evaluate the level-of-frozenness (LOF) of large blocks of food products (e.g. blocks of meat) or layers of products (e.g. French fries). The MICROFREEZE® can easily handle layered products with layer thicknesses up to 50 cm. This makes our sensor ideal for monitoring bulk products such as French fries, vegetables, fruits, etc.

Applications:

| Parameter | CALLIFREEZE® | MICROFREEZE® |

|---|---|---|

| Level-of-Frozenness (LOF) | 70 – 100%* Range depends on the product | 0 – 100%* Range depends on the product |

| Emitted electromagnetic power | ~10 dBm | ~10 dBm |

| Frequency bands | 61.25 GHz Non-ionizing and non-destructive | 2.4 – 2.5 GHz and 5.725 – 5.875 GHz Non-ionizing and non-destructive |

| Sensor’s spot size @ product | ~2 cm | ~15 cm |

| Power input | AC Single Phase 100-240V~ 0.5A 50-60 Hz | AC Single Phase 100-240V~ 0.5A 50-60 Hz |

| Operational temperature range | -40 °C … 40 °C | -40 °C … 40 °C |

| Housing | Stainless steel AISI 304 – Hygienic design | Stainless steel AISI 304 – Hygienic design |

| IP class | IP66 | IP66 |

| Dimensions receiver – transmitter unit (W x H x D) | 177 mm x 187 mm x 178 mm | 177 mm x 187 mm x 178 mm |

| Dimensions computing unit (W x H x D) | 327 mm x 457 mm x 179 mm | 390 mm x 576 mm x 267 mm |

| Ethernet | RJ45 plug | RJ45 plug |

| Industrial interface | Modbus TCP/IP server | Modbus TCP/IP server |

| Web-server based user interface | Remote interaction with the sensor via a browser | Remote interaction with the sensor via a browser |

| DHCP client | Automatic negotiation of IP address | Automatic negotiation of IP address |

| Capacity of LOF calculations | 10 LOF values per second | 1 – 500 LOF values per second |

AI-powered sensors

Artificial Intelligence and Web Interface

The acquired sensor data are fed to our AI-algorithms which provides reliable process information about the freezing and defrosting processes. Depending on the application, our sensors can be combined with other sensing modalities to provide a complete image of the process.

The web interface is used to visualize the processed data and manage the device settings for different products. The software supports Modbus TCP/IP direct communication with PLC units for automatic process control.

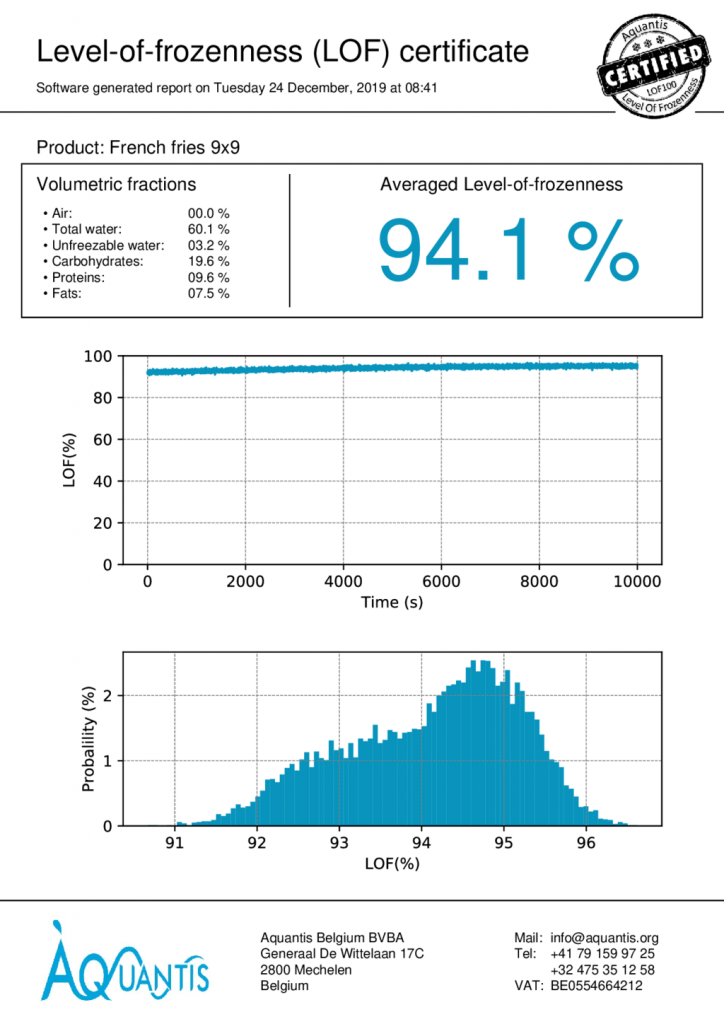

Level Of Frozenness certificate

To meet the increasing demands for quality reporting and traceability of products, our system automatically generates quality reports of all processed data. The report gives an overview of the evaluated products and their respective Level Of Frozenness (LOF) values. Since the products are scanned inline, the quality of every product or batch is checked. The products which are sufficiently frozen, receive the level-of-frozenness certificate to confirm the highest quality standards. This confirmation will enhance the trust of your customers in your freezing processes.